The Toyota 4Runner, a beloved SUV, historically offered a manual transmission, appealing to enthusiasts desiring greater control and a more engaging driving experience.

Despite its enduring popularity, the 2025 4Runner will not feature a manual option, mirroring concerns about transmission issues seen in the Tacoma.

Owners frequently discuss transmission problems, like grinding gears and failures, often opting for used replacements due to repair costs and complexity.

Historical Overview of 4Runner Manual Options

The Toyota 4Runner initially embraced manual transmissions, offering them across several generations to cater to drivers seeking a more connected feel. First-generation (1984-1989) models readily featured five-speed manuals, establishing a tradition for the rugged SUV. This continued into the second generation (1990-1995), though availability varied by year and trim level.

The third generation (1996-2002) saw a gradual decline in manual options, becoming less common as automatic transmissions gained popularity. The fourth generation (2003-2009) largely phased out the manual, with only limited availability in certain markets or early production years.

Recent discussions highlight a nostalgic desire for a manual 4Runner, especially given its availability in the related Toyota Tacoma. However, Toyota has confirmed the 2025 4Runner will not offer a manual transmission, ending a long-standing, albeit dwindling, tradition.

Why the Manual Transmission is Sought After

Manual transmissions in the Toyota 4Runner, and vehicles generally, appeal to enthusiasts for several key reasons. Drivers appreciate the enhanced sense of control, allowing for precise gear selection and a more engaging driving experience, particularly off-road. A manual gearbox fosters a stronger connection between driver and machine, increasing involvement and enjoyment.

Furthermore, many believe manuals offer greater reliability and simpler mechanics compared to automatics, potentially reducing long-term maintenance costs. The ability to engine-brake effectively is another advantage, especially during challenging terrain or towing.

Despite the 2025 4Runner omitting a manual option, the demand persists within the Toyota community, fueled by a desire for a more visceral and driver-focused SUV experience.

Common Toyota 4Runner Manual Transmission Models

Toyota 4Runner manual transmissions spanned several generations, from the first (1984-1989) to the third (1996-2002), offering enthusiasts choices in their SUV.

First Generation (1984-1989) Manual Transmissions

The initial 4Runner models (1984-1989) provided a five-speed manual transmission as a standard option, particularly appealing to drivers seeking a more connected driving experience. These early 4Runners, built on the Hilux chassis, offered a robust and reliable drivetrain.

The W56 transmission was commonly found in these first-generation vehicles, known for its durability, though issues like clutch hydraulic leaks and difficulty engaging gears emerged over time.

Owners often report experiencing grinding noises as a precursor to more significant internal damage, sometimes necessitating a used transmission swap due to repair costs. Despite these potential issues, the first-generation 4Runner’s manual transmission remains a sought-after feature among enthusiasts.

Second Generation (1990-1995) Manual Transmissions

The second-generation 4Runner (1990-1995) continued to offer a five-speed manual transmission, maintaining its appeal for drivers prioritizing control and engagement. These models saw refinements in the chassis and suspension, enhancing overall driving dynamics.

The W56 transmission remained prevalent during this period, though reports of clutch issues and gear engagement difficulties persisted, mirroring concerns from the first generation. Some owners experienced complete transmission failure, leading to the search for used replacements.

Despite these potential drawbacks, the manual transmission in the second-generation 4Runner provided a satisfying driving experience, and remains a desirable feature for enthusiasts today.

Third Generation (1996-2002) Manual Transmissions

The third-generation 4Runner (1996-2002) largely carried over the manual transmission options from its predecessor, primarily utilizing the five-speed W56 gearbox. This generation saw increased refinement in interior comfort and exterior styling, but the manual transmission retained its core functionality.

However, the W56 continued to be a source of potential issues, with owners reporting similar problems to previous generations – clutch hydraulic leaks and difficulty engaging gears, especially under load. Some experienced complete transmission failure, necessitating replacement with used units.

Despite these concerns, the manual 4Runners of this era remain popular among enthusiasts seeking a more connected driving experience.

Fourth Generation (2003-2009) Manual Transmissions

The fourth-generation 4Runner (2003-2009) marked a significant shift in design and features, but the manual transmission offering became increasingly limited. Toyota continued to utilize the R150F five-speed manual, though its availability varied depending on trim level and year.

Owners of these 4Runners also reported common manual transmission issues, including clutch problems and difficulty shifting, mirroring concerns from earlier generations. The R150F, while generally robust, wasn’t immune to wear and tear, sometimes requiring replacement with used units.

This generation represents the last time Toyota offered a manual transmission in the 4Runner, making these models highly sought after by enthusiasts.

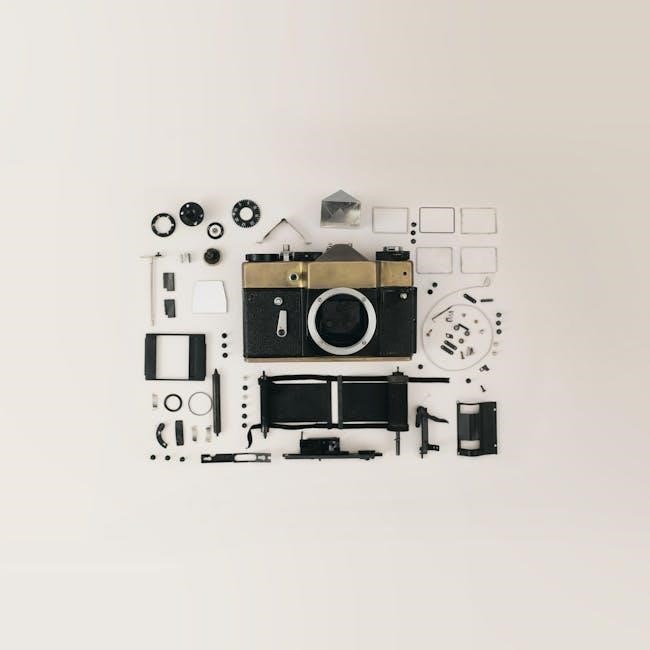

Technical Specifications of 4Runner Manual Transmissions

Toyota 4Runner manual transmissions, like the W56 and R150F, feature specific gear ratios and differential options impacting performance.

Understanding these specs is crucial for maintenance, repair, and potential performance upgrades for these robust systems.

Gear Ratios and Differential Options

Toyota 4Runner manual transmissions utilized varying gear ratios depending on the specific model year and engine configuration, significantly influencing acceleration and fuel economy.

First gear ratios were typically optimized for off-road crawling, while higher gears focused on highway cruising efficiency.

Differential options, including open, limited-slip, and locking differentials, further enhanced the 4Runner’s capabilities.

These differentials distributed power to the wheels, improving traction in challenging terrains.

The combination of gear ratios and differential choices allowed 4Runner owners to tailor their vehicle’s performance to their specific needs.

Understanding these specifications is vital for optimizing the 4Runner’s performance and ensuring proper operation of the drivetrain.

Proper gear oil selection is also critical for longevity.

W56 Transmission Details

The W56 was a popular five-speed manual transmission found in early Toyota 4Runner models, known for its durability and relatively simple design.

It’s a robust unit, but owners report issues like getting stuck in gear and experiencing grinding noises, often indicating internal wear or damage.

The W56 features a cast-iron case and is generally considered capable of handling moderate power increases.

However, prolonged abuse or lack of maintenance can lead to failure, necessitating a rebuild or replacement.

Finding parts for the W56 can be challenging, with some components becoming increasingly scarce.

Proper fluid changes and careful driving habits are crucial for extending the W56’s lifespan.

Many owners eventually opt for a used replacement when major issues arise.

R150F Transmission Details

The R150F is a heavier-duty five-speed manual transmission utilized in later Toyota 4Runner generations, offering increased strength compared to the W56.

It’s favored for its ability to withstand higher torque levels, making it suitable for modified or lifted 4Runners.

Like the W56, the R150F can experience issues, though typically after more demanding use.

Common problems include clutch hydraulic leaks and difficulty engaging gears, particularly under load.

Internal damage leading to grinding noises is also reported, signaling potential bearing or gear wear.

Regular maintenance, including fluid changes, is vital for preventing premature failure.

Sourcing parts for the R150F is generally easier than for the W56, but rebuilds can still be costly.

Potential Problems with 4Runner Manual Transmissions

4Runner manual transmissions are prone to clutch hydraulic leaks, gear engagement difficulties, and grinding noises indicating internal damage, sometimes leading to complete failure.

Clutch Hydraulic Leaks

Clutch hydraulic leaks represent a common issue within Toyota 4Runner manual transmissions, frequently reported by owners across various generations. These leaks typically originate from the master cylinder or slave cylinder, components crucial for transmitting force from the pedal to the clutch.

Symptoms include a spongy or soft pedal feel, difficulty engaging gears, and, in severe cases, the inability to shift at all. Over time, lost fluid reduces hydraulic pressure, impacting clutch disengagement. Addressing these leaks promptly is vital to prevent further damage to the transmission itself.

Repair often involves replacing the leaking cylinder(s) and thoroughly bleeding the hydraulic system to remove air bubbles, restoring proper clutch operation. Ignoring these leaks can lead to costly transmission repairs down the line.

Difficulty Engaging Gears

Difficulty engaging gears is a frequently cited problem with Toyota 4Runner manual transmissions, often stemming from several underlying causes. Owners report struggles, particularly when shifting into first or reverse, or experiencing resistance when moving between gears under load.

Potential culprits include worn synchronizers, a failing master or slave cylinder (related to hydraulic issues), or internal transmission damage. A worn clutch can also contribute, failing to fully disengage the engine from the transmission. This makes smooth gear changes impossible.

Troubleshooting involves inspecting the clutch, hydraulic system, and potentially a transmission rebuild to address worn internal components. Ignoring this issue can lead to further damage and eventual transmission failure.

Grinding Noises and Internal Damage

Grinding noises emanating from the Toyota 4Runner manual transmission are a serious warning sign of potential internal damage. These sounds often indicate worn or broken synchronizers, responsible for matching gear speeds during shifts. Prolonged grinding accelerates wear on gear teeth, leading to chipped or broken components.

Owners have reported sounds “like rocks in the transmission,” signifying significant internal deterioration. Ignoring these noises can result in complete gear failure, rendering the transmission unusable. Internal damage can also stem from insufficient lubrication or aggressive shifting habits.

Diagnosis typically requires a transmission inspection, potentially involving disassembly to assess the extent of the damage. Repair often necessitates replacing synchronizers, gears, and bearings.

Transmission Failure and Replacement

Toyota 4Runner manual transmission failure can manifest as complete loss of function, inability to shift, or catastrophic internal damage. When repairs become economically unfeasible, transmission replacement is often the most practical solution. Owners facing this situation frequently turn to the used market, as sourcing a rebuilt or new unit can be costly.

Finding a suitable used transmission requires careful inspection to ensure its condition. Thoroughly vetting the seller and obtaining a warranty are crucial steps. Alternatively, a professional rebuild offers a more reliable, albeit expensive, option.

Replacement involves disconnecting driveshafts, linkages, and electrical connections, demanding mechanical expertise.

Maintenance and Repair of 4Runner Manual Transmissions

Regular fluid changes are vital for longevity, alongside addressing clutch hydraulic leaks promptly. Troubleshooting common issues requires expertise, and finding a qualified mechanic is key.

Fluid Changes and Recommendations

Maintaining the correct fluid level and condition is paramount for a healthy Toyota 4Runner manual transmission. Regular fluid changes ensure optimal lubrication, reducing wear and tear on internal components like gears and synchronizers.

Generally, it’s recommended to change the manual transmission fluid every 30,000 to 60,000 miles, depending on driving conditions. Severe duty, such as frequent off-roading or towing, necessitates more frequent changes.

Using the correct fluid type is crucial; consult your owner’s manual for specifications. Many 4Runners utilize GL-4 gear oil, but verifying the correct viscosity is essential. Avoid mixing different fluid types.

During a fluid change, inspect the drain plug for metal shavings, indicating potential internal damage. A magnetic drain plug can help capture these particles. Proper fluid maintenance significantly extends the life of your 4Runner’s manual transmission.

Clutch Replacement Procedures

Replacing the clutch in a Toyota 4Runner manual transmission is a complex task, best undertaken by experienced mechanics. The procedure involves disconnecting the driveshaft, exhaust, and various linkages. Accessing the transmission typically requires removing the transfer case and potentially lifting the engine slightly.

Once the transmission is removed, the clutch disc, pressure plate, and throw-out bearing are inspected for wear. Replacing the pilot bearing is also recommended. Aligning the clutch disc correctly during installation is critical to prevent premature failure.

Thoroughly cleaning the flywheel surface and checking for warping are essential steps. Reassembly requires careful attention to torque specifications for all bolts. Bleeding the hydraulic clutch system is vital for proper operation.

Troubleshooting Common Issues

Toyota 4Runner manual transmissions exhibit several recurring problems. Difficulty engaging gears, particularly under load, often points to a failing clutch or hydraulic issues; Grinding noises frequently indicate worn synchronizers within the transmission itself, potentially requiring a rebuild.

Clutch hydraulic leaks are prevalent, leading to a soft or unresponsive pedal; Inspect the master and slave cylinders, along with the hydraulic lines, for any signs of leakage. Internal transmission damage can manifest as complete gear failure, necessitating a replacement.

Careful diagnosis is crucial; check fluid levels and look for external leaks before assuming major internal problems. Online forums offer valuable insights from experienced owners facing similar challenges.

Finding Qualified Mechanics

Locating a mechanic experienced with Toyota 4Runner manual transmissions is vital for accurate diagnosis and repair. Many general mechanics lack the specialized knowledge required for these systems.

Seek out shops specializing in Japanese vehicles or those with a proven track record of transmission work. Online Toyota forums are excellent resources for recommendations within your region; owner experiences provide valuable insights.

Verify the mechanic’s certifications and inquire about their familiarity with the W56 or R150F transmissions commonly found in 4Runners. A skilled technician can differentiate between simple fixes and complex internal issues, saving you time and money.

Sourcing Parts for 4Runner Manual Transmissions

Finding parts requires considering new, used, or aftermarket options; used transmissions are common solutions due to cost, while performance upgrades exist.

Online retailers and forums offer parts, but verifying quality and compatibility is crucial for a successful repair or modification.

New vs. Used Transmission Options

Choosing between a new and used Toyota 4Runner manual transmission presents distinct advantages and disadvantages for owners facing repair or replacement needs.

New transmissions, while significantly more expensive, offer the peace of mind of a full warranty and the assurance of untouched internal components, minimizing immediate repair concerns.

However, sourcing a brand-new 4Runner manual transmission can be challenging, given their limited production in recent years and potential scarcity.

Used transmissions, conversely, are often more readily available and considerably cheaper, making them a popular choice for budget-conscious owners.

However, used units come with inherent risks, including unknown wear and tear, potential for hidden damage, and a limited or nonexistent warranty.

Thorough inspection, ideally by a qualified mechanic, is crucial before purchasing a used transmission to assess its condition and minimize the risk of future failures.

Careful consideration of budget, risk tolerance, and availability should guide the decision-making process.

Aftermarket Performance Upgrades

For Toyota 4Runner manual transmission enthusiasts seeking enhanced durability or performance, a range of aftermarket upgrades are available, though options are somewhat limited due to the decreasing prevalence of manual models.

Clutch kits offering increased clamping force are popular, improving shift quality and handling increased engine power, particularly beneficial for off-road modifications.

Short-throw shifters can reduce throw length, resulting in quicker, more precise gear changes, enhancing the driving experience.

Strengthened gears and internal components can improve the transmission’s ability to withstand the stresses of demanding terrain and heavy use.

However, it’s crucial to select reputable brands and ensure compatibility with the specific 4Runner generation and transmission model.

Professional installation is highly recommended to guarantee proper fitment and avoid potential damage.

Careful research and consideration of driving style are essential when choosing aftermarket upgrades.

Online Parts Retailers

Sourcing parts for Toyota 4Runner manual transmissions can be challenging due to their age and decreasing availability, making online retailers a crucial resource.

RockAuto is a popular choice, known for its extensive catalog and competitive pricing, offering both new and used components.

eBay provides a vast marketplace for both individual parts and complete transmissions, requiring careful vetting of sellers and part conditions.

Toyota Parts Dealerships online offer genuine OEM parts, ensuring compatibility but often at a higher cost.

Specialty Toyota parts websites cater specifically to older models, potentially stocking hard-to-find items.

Always verify the part number and compatibility with your specific 4Runner year and transmission type before purchasing.

Consider shipping costs and return policies when comparing retailers.

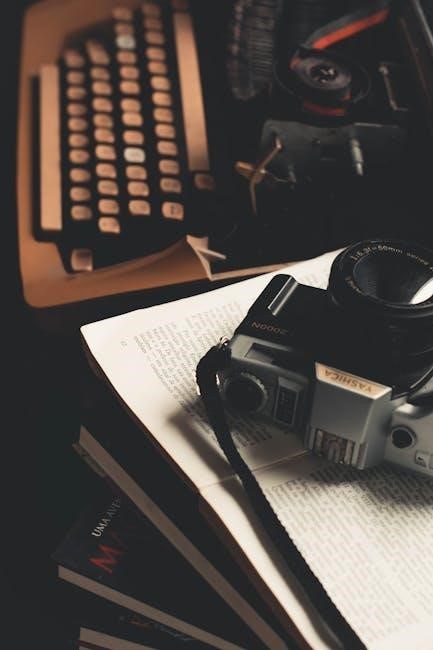

The 2025 4Runner and the Absence of a Manual Transmission

Toyota confirmed the 2025 4Runner won’t offer a manual, unlike the Tacoma, declining to comment on future availability amid transmission concerns.

Comparison to the Toyota Tacoma

The 2025 Toyota Tacoma notably does offer a manual transmission, creating a stark contrast with the 4Runner’s omission of this option.

This difference has fueled speculation and disappointment among 4Runner enthusiasts, particularly those who value a driver-focused experience.

Interestingly, the Tacoma has experienced reported transmission “gremlins” – complaints from owners regarding its performance – raising questions about Toyota’s decision-making.

Some theorize that these Tacoma transmission issues influenced the choice to forgo a manual 4Runner, potentially avoiding similar problems.

However, Toyota has remained tight-lipped about the specific reasons, only stating they haven’t commented on future manual offerings.

The Tacoma’s availability with a stick shift highlights a clear divergence in Toyota’s strategy for these two popular off-road vehicles.

Reasons for Discontinuation

Toyota has not explicitly detailed the reasons for discontinuing the manual transmission in the 2025 4Runner, leaving enthusiasts to speculate.

A prevailing theory suggests potential concerns stemming from reported transmission issues within the mechanically similar Toyota Tacoma, which does offer a manual.

Avoiding potential warranty claims and negative publicity related to transmission problems could be a significant factor in this decision.

Declining overall demand for manual transmissions in the broader automotive market also likely played a role, influencing Toyota’s product strategy.

Production complexities and the increased cost of offering a manual variant in a relatively low-volume configuration may have contributed.

Ultimately, a combination of these factors likely led to the omission of the manual option in the new 4Runner.

Future Possibilities for a Manual 4Runner

Toyota representatives have declined to comment on the possibility of a future manual 4Runner, leaving the door slightly ajar for potential reconsideration.

Strong advocacy from the 4Runner enthusiast community, demonstrated through online forums and direct feedback to Toyota, could influence future product planning.

If transmission gremlins in the Tacoma are successfully addressed, it might pave the way for reintroducing a manual option in the 4Runner at a later date.

A limited-edition, enthusiast-focused 4Runner trim with a manual transmission could be a viable strategy to gauge demand and generate excitement.

However, given current market trends, a return of the manual is not guaranteed and remains highly speculative.

Continued pressure from dedicated fans is key to keeping the possibility alive.

Community Forums and Resources

Online forums are vital for 4Runner owners, offering technical documentation, troubleshooting advice, and shared experiences regarding manual transmissions.

These platforms provide a space to discuss issues like clutch problems and gear grinding, fostering a collaborative problem-solving environment.

Popular Online Forums

Toyota 4Runner enthusiasts actively participate in several online forums dedicated to the vehicle, providing a wealth of information regarding manual transmissions. Toyota Nation and YotaTech are frequently cited as excellent resources, hosting extensive threads on common issues, repair procedures, and parts sourcing.

These forums allow owners to connect, share their experiences with W56 and R150F transmissions, and seek advice from experienced mechanics and fellow enthusiasts. Discussions often revolve around clutch hydraulic leaks, difficulty engaging gears, and diagnosing grinding noises.

IH8MUD is another prominent forum, known for its detailed technical discussions and comprehensive guides. Members regularly post about transmission failures, used transmission options, and aftermarket performance upgrades. These platforms are invaluable for anyone owning or considering a manual 4Runner.

Technical Documentation and Guides

Comprehensive repair manuals, such as those from Haynes or Chilton, offer detailed diagrams and step-by-step instructions for servicing Toyota 4Runner manual transmissions. These guides cover everything from fluid changes to clutch replacement procedures and troubleshooting common issues.

Online resources, including Toyota’s official technical service manuals (often available through subscription services), provide in-depth specifications and diagnostic information. Several websites compile user-generated guides focusing on specific problems, like addressing clutch hydraulic leaks or gear engagement difficulties.

YouTube hosts numerous videos demonstrating manual transmission repairs and maintenance. These visual aids can be incredibly helpful, especially for tackling complex procedures. Accessing these resources is crucial for successful DIY repairs and understanding the intricacies of the W56 and R150F transmissions.

Owner Experiences and Reviews

Toyota 4Runner manual transmission owners frequently share experiences on online forums, detailing both the joys and challenges of their vehicles. Many praise the engaging driving experience and robust feel of the manual gearbox, particularly in off-road situations.

However, recurring themes emerge regarding potential issues. Owners report instances of clutch hydraulic leaks, difficulty engaging gears, and concerning grinding noises, sometimes leading to complete transmission failure. Several owners opted for used transmission replacements due to the high cost of repairs.

Reviews highlight the importance of proactive maintenance, including regular fluid changes, to mitigate potential problems. Overall, owner feedback suggests a rewarding but potentially demanding ownership experience.

Cost Analysis: Manual 4Runner Ownership

Manual 4Runners often command a premium purchase price due to their rarity and desirability. Maintenance costs are comparable, but potential transmission repairs can be expensive.

Used transmission swaps are common, adding significant cost, while clutch replacements are routine expenses.

Purchase Price Comparison

Historically, Toyota 4Runners equipped with manual transmissions consistently command a higher resale value than their automatic counterparts. This price difference stems from the limited availability of manual models, creating increased demand among enthusiasts who specifically seek this configuration.

Currently, finding a well-maintained manual 4Runner requires diligent searching and a willingness to potentially pay a premium. Depending on the generation, condition, and mileage, expect to add anywhere from $2,000 to $5,000 – or even more – to the purchase price compared to a similar automatic model.

First and second-generation models, particularly those in excellent condition, often see the largest premiums. The scarcity of these older manual 4Runners drives up collector interest and, consequently, their market value. Newer, third and fourth-generation manual 4Runners also hold their value well, though the price gap may be slightly smaller.

It’s crucial to factor this initial cost difference into your overall budget when considering manual 4Runner ownership.

Maintenance Costs

Maintaining a Toyota 4Runner with a manual transmission generally aligns with the costs of an automatic model for routine services like oil changes, filter replacements, and fluid checks. However, the manual transmission introduces specific components requiring periodic attention.

Clutch maintenance is the most significant additional expense. Clutch replacement, depending on driving habits and component quality, typically falls between $800 and $1,500, including parts and labor. Hydraulic clutch systems are prone to leaks, necessitating fluid flushes and potential master/slave cylinder replacements.

Regularly inspecting and adjusting the clutch cable (on older models) is vital. Transmission fluid changes, while less frequent than automatic fluid services, are crucial for longevity. Expect slightly higher labor costs for manual transmission-specific repairs due to the increased mechanical complexity.

Proactive maintenance minimizes long-term expenses.

Potential Repair Expenses

Toyota 4Runner manual transmissions, while robust, aren’t immune to failures, leading to potentially significant repair expenses. Clutch issues are common, with replacements ranging from $800 to $1,500, including parts and labor. Hydraulic clutch leaks, requiring master/slave cylinder replacements, can add $300-$600 to the bill.

Internal transmission damage, evidenced by grinding noises, necessitates a rebuild or replacement. A transmission rebuild can cost $1,500 ⎻ $3,000, while a used transmission might range from $800 to $2,000 plus installation. Difficulty engaging gears often signals worn synchronizers or shift forks.

Diagnosing these issues requires a skilled mechanic, adding to the overall cost. Ignoring early warning signs can escalate repairs dramatically, potentially leading to complete transmission failure.