The Honeywell Vista 20P is a reliable, versatile security system designed for residential and commercial use, offering advanced features like remote access, multiple security modes, and seamless integration with other devices.

1.1 Overview of the Vista 20P Series

The Vista 20P series, including Vista-20PSIA and Vista-15P, offers a reliable and versatile security solution for residential and commercial use. Designed for flexibility, these systems support advanced features like partitioning, remote access, and integration with various sensors and devices. The Vista 20P is known for its robust security capabilities, user-friendly interface, and compatibility with modern communication technologies, making it a popular choice for diverse security needs.

1.2 Key Features and Benefits

The Vista 20P series offers advanced security solutions with features like multiple security modes (Stay, Night-Stay, Away), remote access capabilities, and compatibility with a wide range of sensors. It supports up to 48 security codes and provides flexible partitioning for independent zone control. The system is designed for easy integration with video surveillance and other smart devices, ensuring enhanced security and convenience for users. Its robust design and user-friendly interface make it a reliable choice for both residential and commercial applications.

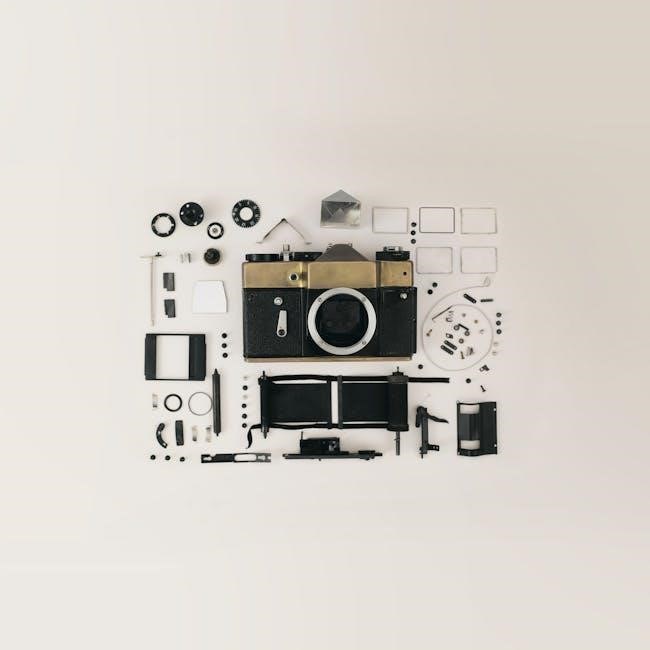

System Components and Hardware

The Vista 20P includes a control panel, key modules, and a range of sensors for comprehensive security coverage, supporting up to 48 zones and advanced communication modules.

2.1 Control Panel and Key Modules

The Vista 20P control panel serves as the system’s core, managing security operations and integrating with key modules like keypads, communication devices, and sensors. It supports up to 48 zones, offering flexibility for various security needs. Key modules include the 6160 alphanumeric keypad for programming and the 6280 touchscreen keypad for enhanced user interaction. The system also supports advanced communication modules like AlarmNet for remote monitoring and control, ensuring reliable security management and connectivity.

2.2 Sensors and Zone Configuration

The Vista 20P supports a wide range of sensors, including door/window contacts, motion detectors, and glassbreak sensors, ensuring comprehensive security coverage. Zones can be configured to monitor specific areas, with options for entry/exit, perimeter, or interior protection. Each sensor is assigned to a zone, allowing for customized responses and alerts. Proper sensor placement and zone configuration are essential for reliable performance and minimizing false alarms.

Installation and Setup

The Vista 20P installation involves mounting the control panel, wiring sensors, and configuring zones. Follow the manual for step-by-step setup and programming instructions to ensure proper system functionality.

3.1 Mounting and Wiring Sensors

Mount sensors securely at entry points like doors and windows. Wired sensors connect to the control panel’s zone terminals. Ensure proper alignment and secure fastening. Follow the manual’s wiring diagram for accurate connections. Test sensors post-installation to confirm functionality. Incorrect wiring may void the warranty or compromise system performance. Always refer to the Vista 20P manual for specific installation guidelines and safety precautions.

3.2 Connecting to the Control Panel

Connect sensors to the Vista 20P control panel by linking wires to designated zone terminals. Ensure all connections are secure and match the system’s wiring diagram. For wireless sensors, synchronize them with the panel by following the manual’s enrollment process. Proper connections ensure reliable performance and accurate alarm responses. Always verify connections after setup and test the system to confirm functionality.

Programming the Vista 20P

Program the Vista 20P by accessing programming mode using the installer code and specific keypad commands. Configure zones, security modes, and advanced settings to customize system behavior and ensure optimal security.

4.1 Accessing Programming Mode

To access programming mode on the Vista 20P, power up the system and press the appropriate keys within 50 seconds. Use the installer code followed by 800 to enter programming. This allows configuration of zones, security modes, and advanced settings. Ensure the system is in the correct state before starting. Refer to the manual for specific keypad commands and procedures. This step is essential for customizing the system to meet your security needs.

4.2 Zone Programming and Configuration

Zone programming allows customization of each sensor’s function within the Vista 20P system. Assign zone types like entry/exit, perimeter, or interior. Configure response types and thresholds for accurate detection. Use the 56 zone programming menu to select unused zones and set parameters. Ensure proper enrollment of wireless sensors by activating them and verifying their serial numbers. This step ensures optimal security coverage and tailored system response to different scenarios, enhancing overall protection and reliability.

4.3 Partitioning and Advanced Settings

The Vista 20P supports up to two independent partitions, allowing separate security control for different areas. Advanced settings include custom user codes, event scheduling, and system-wide configurations. Partitioning enables arming/disarming specific zones without affecting others. Additional features like duress codes and system-wide macros enhance security. These settings provide flexibility for tailored security solutions, ensuring the system adapts to diverse user needs and premises layouts effectively.

System Features and Capabilities

The Vista 20P offers advanced security modes, remote access, and communication options like IP, 4G, or LTE. It supports up to 150 user codes and 250 access cards via VistaKey for enhanced convenience and security.

5.1 Security Modes (Stay, Night-Stay, Away)

The Vista 20P offers multiple security modes to suit different scenarios. Stay mode arms perimeter sensors while allowing free movement indoors. Night-Stay mode provides perimeter protection with selective interior zones disarmed. Away mode enables full system protection with optional entry/exit delays. These modes ensure tailored security, enhancing system flexibility and user convenience for various lifestyles and premises. The system adapts seamlessly to changing security needs, providing reliable protection in every situation.

5.2 Remote Access and Communication

The Vista 20P supports remote access through AlarmNet communicators, enabling users to arm/disarm the system, receive alerts, and monitor status via mobile apps. IP, 4G, or LTE communication ensures reliable connectivity. Remote access enhances convenience, allowing real-time system control and notifications from anywhere. This feature is especially useful for users seeking enhanced security management and peace of mind, even when away from their premises, leveraging modern communication technologies effectively.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance. Check sensors, wiring, and system updates. Troubleshooting common issues like sensor malfunctions or connectivity problems can be resolved through diagnostics and resets.

6.1 Regular System Maintenance

Regular maintenance is crucial for ensuring the Vista 20P system operates efficiently. Inspect sensors and wiring for damage or wear. Test all zones monthly to confirm proper functionality. Replace batteries in wireless devices as needed. Check system logs for errors and update firmware periodically. Clean keypad surfaces and ensure all connections are secure. Scheduling annual professional inspections is recommended to address potential issues before they escalate.

6.2 Common Issues and Solutions

Common issues with the Vista 20P include false alarms, sensor malfunctions, and communication errors. For false alarms, check sensor alignment and adjust sensitivity settings. Malfunctioning sensors may need cleaning or replacement. Communication issues can be resolved by verifying panel connections and restarting the system. Refer to the user manual for troubleshooting guides or contact technical support for advanced assistance. Regular maintenance helps prevent these issues.

Compatibility and Integration

The Vista 20P integrates seamlessly with Honeywell’s Total Connect, IP modules, and LTE communicators, enabling remote monitoring and control. It supports various sensors and smart home systems.

7.1 Compatible Sensors and Devices

The Vista 20P supports a wide range of sensors, including door/window contacts, motion detectors, glassbreak sensors, and smoke detectors. It is compatible with both wired and wireless devices, allowing for flexible system customization. Additionally, it works seamlessly with Honeywell’s Total Connect communicators and AlarmNet devices, enhancing remote monitoring capabilities and system reliability. This ensures comprehensive security coverage and integration with modern smart home systems.

7.2 Integration with Other Systems

The Vista 20P integrates seamlessly with Honeywell’s Total Connect platform, enabling remote monitoring and control via smartphones or tablets. It also supports integration with third-party smart home systems and Z-Wave devices, allowing users to control lighting, thermostats, and security from a single interface. Additionally, it works with voice assistants like Amazon Alexa for enhanced convenience and hands-free system management.

Best Practices for Use

Regularly test sensors, update user codes, and ensure optimal sensor placement for maximum coverage. Train users on system operation and review settings periodically for enhanced security and efficiency.

8.1 Optimizing Sensor Placement

Strategically place sensors at all entry points, including doors, windows, and skylights. Ensure coverage in high-risk areas like basements and garages. For motion detectors, position them in corners for wide-angle coverage. Avoid obstructions and ensure sensors are level for reliable performance. Regularly inspect and clean sensors to maintain accuracy. Proper placement enhances system effectiveness and reduces false alarms, ensuring comprehensive security coverage.

8.2 Managing User Codes and Access

Create strong, unique user codes for each individual, ensuring they are updated regularly. Set access levels based on user roles to restrict unauthorized entry. Regularly review and revoke unused or outdated codes. Use the system’s capacity for up to 150 user codes and 250 access cards for efficient management. Enable two-factor authentication for enhanced security. Maintain a record of all user access changes to monitor system integrity effectively.

The Honeywell Vista 20P security system offers a comprehensive, reliable, and versatile solution for modern security needs. Its advanced features, including multiple security modes, remote access, and integration capabilities, make it suitable for both residential and commercial applications. Regular updates and proper maintenance ensure optimal performance. This manual provides detailed guidance to maximize the system’s potential, ensuring robust protection and peace of mind for users.