Mental health care exists on a continuum, ranging from outpatient services to residential treatment, ensuring individuals receive appropriate support.

Providers consistently assess a person’s needs, evaluating safety and daily living skills to determine the optimal level of intervention.

Defining the Continuum of Care

The mental health continuum of care represents a comprehensive, coordinated network of services designed to address the diverse needs of individuals experiencing mental health challenges. This system isn’t a rigid set of steps, but rather a flexible framework encompassing outpatient therapy, Intensive Outpatient Programs (IOPs), Partial Hospitalization Programs (PHPs), inpatient hospitalization, and residential treatment centers.

Each level offers varying degrees of intensity and support, tailored to the individual’s specific condition and functional abilities. Effective care involves ongoing assessment to ensure individuals are placed at the most appropriate level, promoting optimal outcomes and preventing unnecessary escalation or under-treatment.

Importance of Appropriate Level of Care

Selecting the correct level of care is paramount in mental health treatment, directly impacting a patient’s progress and overall well-being. Insufficient care can lead to symptom exacerbation and increased safety risks, while overly intensive treatment may be disruptive and unnecessary.

Providers have a responsibility to consistently evaluate an individual’s “fit” for their current level of support, considering their mental health status, ability to perform daily living skills, and potential risks to themselves or others. Accurate assessment ensures resources are allocated effectively, maximizing positive outcomes and fostering a path towards lasting recovery.

Outpatient Mental Health Care

Outpatient care forms the foundation of mental health support, encompassing therapy, counseling, and psychiatric medication management for individuals with stable conditions.

Traditional Therapy & Counseling

Traditional therapy and counseling represent a cornerstone of outpatient mental health care, offering a safe and supportive environment for individuals to explore their thoughts, feelings, and behaviors.

Various therapeutic approaches, such as cognitive behavioral therapy (CBT), psychodynamic therapy, and humanistic therapy, are utilized to address a wide range of mental health concerns.

These sessions typically involve one-on-one meetings with a licensed therapist or counselor, providing personalized attention and guidance. The goal is to develop coping mechanisms, improve communication skills, and foster emotional well-being, ultimately empowering individuals to manage their mental health effectively.

Psychiatric Medication Management

Psychiatric medication management is a crucial component of outpatient mental health care, often used in conjunction with therapy to address biological imbalances contributing to mental health conditions.

A psychiatrist or psychiatric nurse practitioner evaluates a patient’s needs and prescribes appropriate medications, such as antidepressants, anti-anxiety medications, or mood stabilizers.

Regular follow-up appointments are essential to monitor medication effectiveness, manage side effects, and adjust dosages as needed; This collaborative process ensures patients receive optimal pharmacological support, enhancing their overall treatment outcomes and improving their quality of life.

Group Therapy Options

Group therapy offers a supportive and cost-effective adjunct to individual counseling within outpatient mental health care, fostering a sense of community and shared experience.

Various group formats cater to specific needs, including process groups focusing on interpersonal dynamics, psychoeducational groups teaching coping skills, and support groups providing peer encouragement.

These groups allow individuals to practice social skills, receive feedback, and realize they are not alone in their struggles. Participation can reduce feelings of isolation, enhance self-awareness, and promote personal growth, contributing to improved mental well-being.

Intensive Outpatient Programs (IOP)

IOPs provide structured, frequent treatment—a step up from traditional therapy—for individuals needing more support than weekly sessions can offer, but not requiring hospitalization.

Structure and Frequency of IOP

Intensive Outpatient Programs (IOPs) typically involve group therapy, individual counseling, and skills-based workshops, offering a comprehensive approach to mental health treatment. Sessions are scheduled several times a week, often three to five days, for several hours each day.

This structured format allows for consistent support and monitoring, bridging the gap between less intensive outpatient care and more restrictive inpatient settings. The frequency enables clinicians to closely track progress and adjust treatment plans as needed, fostering a supportive environment for lasting change.

Targeted Patient Populations for IOP

Intensive Outpatient Programs (IOPs) are well-suited for individuals needing more support than traditional outpatient therapy, but who remain safe and stable enough to live at home. Common populations include those with anxiety, depression, trauma, or early stages of substance use disorders.

IOPs also benefit individuals stepping down from inpatient hospitalization or those needing a higher level of care before residential treatment. Young adults and adolescents experiencing significant emotional or behavioral challenges frequently find IOPs particularly helpful, offering a structured path toward improved well-being.

Benefits of Intensive Outpatient Treatment

Intensive Outpatient Programs (IOPs) offer a significant advantage by providing a structured treatment environment without the disruption of inpatient hospitalization. Patients benefit from increased therapeutic support, often including individual, group, and family therapy sessions.

IOPs promote skill development in areas like coping mechanisms, emotional regulation, and relapse prevention. The programs’ frequency and intensity allow for rapid progress, while maintaining connections to family and community. This level of care is often more affordable than inpatient options, increasing accessibility.

Partial Hospitalization Programs (PHP)

PHP serves as a crucial bridge, offering a structured daily schedule with therapeutic interventions, yet allowing patients to return home each evening.

PHP as a Bridge Between IOP and Inpatient

Partial Hospitalization Programs (PHP) occupy a vital middle ground within the mental health continuum of care. They represent a less restrictive alternative to full inpatient hospitalization, offering a more intensive level of support than traditional Intensive Outpatient Programs (IOP).

PHP is frequently utilized when an individual requires more structured support and monitoring than IOP can provide, but doesn’t currently necessitate the 24/7 supervision of an inpatient setting. This makes it an ideal step-down option for those transitioning from inpatient care, or a step-up for those whose needs have escalated beyond what outpatient services can safely address.

Essentially, PHP aims to prevent hospitalization or facilitate a successful return to lower levels of care.

Daily Schedule and Therapeutic Interventions in PHP

Partial Hospitalization Programs (PHP) typically feature a structured, full-day schedule, mirroring the intensity of inpatient care without overnight stays. A typical day includes a variety of therapeutic interventions designed to address individual needs.

These commonly encompass group therapy, individual counseling sessions, skills-based workshops (like coping mechanisms or relapse prevention), and psychoeducational sessions. Many programs also integrate family therapy to support the healing process.

Furthermore, PHP often incorporates art or music therapy, and mindfulness practices, fostering holistic well-being. The goal is to provide comprehensive support and equip patients with tools for sustained recovery.

Criteria for PHP Admission

Admission to a Partial Hospitalization Program (PHP) generally requires a diagnosis of a mental health condition that significantly impairs functioning, but doesn’t necessitate 24/7 inpatient hospitalization. Individuals often benefit from PHP if they exhibit moderate symptom severity and require more intensive support than traditional outpatient care provides.

A crucial factor is the individual’s ability to maintain safety within a less restrictive environment. A comprehensive evaluation assesses their current mental health status, evaluating daily living skills and potential risks to themselves or others.

PHP is often considered for those needing a “step-down” from inpatient care or a “step-up” from standard outpatient treatment.

Inpatient Hospitalization for Mental Health

Inpatient care is reserved for individuals experiencing severe mental health crises, posing immediate danger to themselves or others, requiring 24/7 monitoring and stabilization.

Reasons for Inpatient Psychiatric Care

Inpatient hospitalization becomes necessary when an individual’s mental health condition significantly impairs their ability to function safely or effectively in less restrictive settings.

This often includes acute symptoms of depression, anxiety, psychosis, or suicidal ideation with a plan.

Severe self-harm behaviors, threats of violence towards others, or an inability to care for basic needs – like eating, sleeping, or maintaining hygiene – also necessitate this level of care.

Furthermore, individuals experiencing a dangerous withdrawal from substances, or those requiring intensive medication adjustments under close observation, may require inpatient stabilization.

Ultimately, the goal is to provide a secure environment for immediate safety and symptom management.

Safety and Stabilization in a Hospital Setting

Inpatient psychiatric hospitals prioritize creating a safe and supportive environment for patients experiencing acute mental health crises.

Constant monitoring by trained staff minimizes risks associated with self-harm or harm to others, ensuring immediate intervention when needed.

Medication management is closely supervised, allowing for rapid adjustments to optimize symptom control.

Therapeutic interventions, such as group therapy and individual counseling, begin to address underlying issues while promoting coping skills.

The focus is on stabilizing acute symptoms and establishing a foundation for continued recovery.

Length of Stay and Discharge Planning

Inpatient hospitalization length varies significantly, dependent on the severity of symptoms and individual progress, typically ranging from a few days to several weeks.

Discharge planning begins upon admission, involving a collaborative effort between the patient, family, and treatment team.

This process ensures a smooth transition to a lower level of care, such as outpatient therapy or an Intensive Outpatient Program (IOP).

Crucially, it includes arranging follow-up appointments, medication management, and connecting patients with community resources.

A comprehensive discharge plan maximizes the likelihood of sustained recovery and prevents relapse.

Residential Treatment Centers

Residential centers offer long-term support within a therapeutic community, focusing on skill-building and improving daily living skills for sustained wellness.

Long-Term Support and Skill Building

Residential treatment centers distinguish themselves by providing an extended duration of care, fostering deep and lasting change. Unlike shorter-term interventions, these facilities prioritize the development of crucial life skills essential for independent functioning and sustained recovery.

This includes areas like social skills, emotional regulation, problem-solving, and independent living abilities. Through consistent therapeutic support and a structured environment, residents gain the tools and confidence needed to navigate challenges and maintain their mental well-being long after discharge.

The focus extends beyond symptom management to encompass holistic growth and the establishment of a fulfilling life.

Therapeutic Community Environment

Residential treatment centers cultivate a unique therapeutic community where residents and staff collaborate to create a supportive and healing atmosphere. This isn’t merely a place of treatment, but a living laboratory for practicing healthy interpersonal dynamics and building strong relationships.

Residents actively participate in community meetings, group activities, and shared responsibilities, fostering a sense of belonging and mutual accountability. This peer-supported environment encourages empathy, self-awareness, and the development of prosocial behaviors.

The community itself becomes a powerful therapeutic tool, mirroring real-world social interactions and providing opportunities for growth.

Focus on Daily Living Skills

Residential treatment prioritizes rebuilding essential daily living skills often impaired by mental health challenges. This goes beyond therapy, encompassing practical training in areas like personal hygiene, meal preparation, and maintaining a clean living space.

Individuals learn or relearn skills necessary for independent functioning, including budgeting, time management, and responsible medication adherence. Vocational training and educational support are frequently integrated, preparing residents for future employment or academic pursuits.

The goal is to empower individuals with the confidence and competence to successfully navigate everyday life post-treatment.

Assessment and Determining Level of Care

Evaluation of mental health, safety risks, and functional abilities are crucial for determining the most appropriate level of care for each individual.

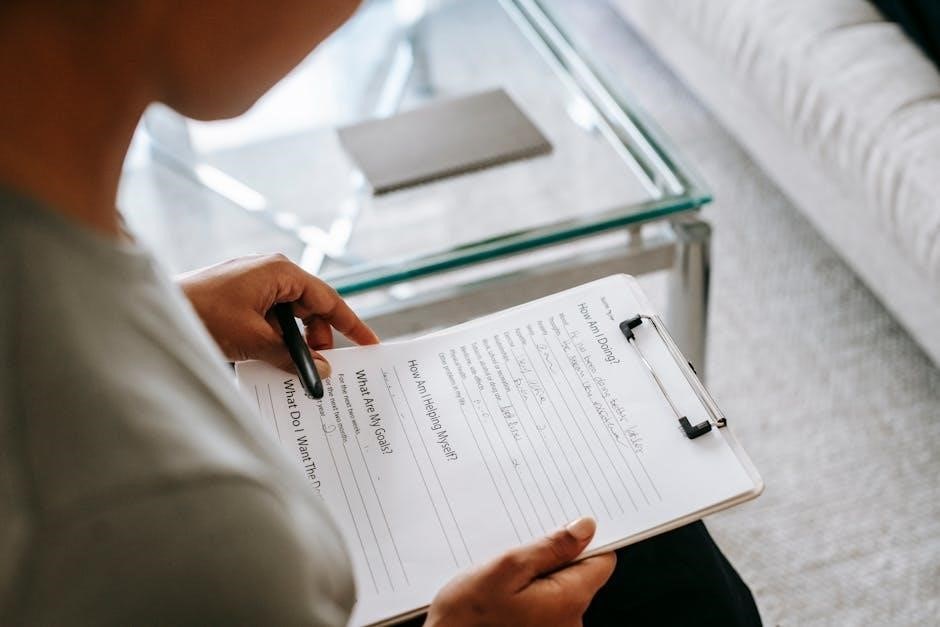

Evaluating Mental Health Status

A thorough assessment of an individual’s current mental health is the foundational step in determining the most effective level of care. This process involves a comprehensive evaluation of symptoms, including their severity, duration, and impact on daily functioning.

Mental health professionals utilize various tools, such as clinical interviews and standardized questionnaires, to gather information about a person’s emotional, behavioral, and cognitive state.

Understanding the specific diagnosis, if any, is also critical, as different conditions may require different treatment approaches and intensities. The evaluation considers the individual’s history of mental health challenges, previous treatments, and any co-occurring medical conditions.

Assessing Safety Risks (Self & Others)

A paramount concern in mental health evaluation is assessing the risk of harm to self or others. This involves directly inquiring about suicidal ideation, intent, and plans, as well as any history of self-harm behaviors.

Professionals also explore potential for harm towards others, including homicidal thoughts, aggressive impulses, and a history of violent behavior. Evaluating the presence of risk factors, such as substance use, trauma, and access to means, is crucial.

Determining the immediacy and severity of these risks directly influences the recommended level of care, potentially necessitating immediate hospitalization or a higher intensity of treatment.

Functional Assessment & Daily Living Skills

Evaluating an individual’s ability to perform daily living skills is integral to determining the appropriate level of mental health care. This assessment encompasses areas like personal hygiene, meal preparation, medication management, and maintaining a safe living environment.

Significant impairments in these areas suggest a need for more intensive support, such as residential treatment or partial hospitalization. Assessing functional capacity helps identify specific needs and tailor treatment plans accordingly.

The goal is to promote independence and improve quality of life, gradually increasing the individual’s ability to manage daily responsibilities.

Insurance Coverage and Access to Care

Navigating mental health benefits presents challenges, including insurance authorization issues and limited coverage, impacting access to necessary treatment levels.

Challenges with Insurance Authorization

Securing insurance authorization for mental health treatment, particularly for intensive outpatient programs (IOP), partial hospitalization programs (PHP), and residential care, often proves difficult.

Insurance companies frequently require extensive documentation, detailed justifications for the chosen level of care, and pre-authorization for each session, creating administrative burdens for providers.

Denials are common, especially when requesting higher levels of care, forcing clinicians to engage in appeals processes and potentially delaying crucial treatment.

The young teacher’s experience, with only 50% of therapy appointments covered, exemplifies these frustrating limitations, hindering consistent care and recovery.

Navigating Mental Health Benefits

Understanding mental health benefits requires careful review of insurance policies, noting coverage specifics for different levels of care – outpatient therapy, IOP, PHP, and inpatient hospitalization.

Patients should clarify deductibles, co-pays, and any limitations on the number of sessions or types of providers covered.

Many plans require pre-authorization, and understanding the appeal process is crucial if a request is denied.

Resources like the insurance provider’s member services and advocacy organizations can assist in deciphering complex benefits and accessing needed care.

Impact of Coverage on Treatment Access

Insurance coverage significantly influences access to appropriate mental health care levels. Limited coverage or high out-of-pocket costs can delay or prevent individuals from seeking necessary treatment, particularly for intensive programs like PHP or residential care.

Insufficient coverage often leads to individuals utilizing lower levels of care when more intensive intervention is required, potentially worsening their condition.

The young teacher’s experience highlights this issue, with only partial coverage impacting his therapy.

Expanding access requires advocating for improved mental health parity and affordable care options.

Emerging Trends in Mental Health Levels of Care

Telehealth, integrated models, and early intervention programs are transforming mental healthcare delivery, increasing accessibility and focusing on proactive support for youth.

Telehealth and Virtual Mental Health Services

Telehealth is rapidly expanding access to mental health services, offering convenient and flexible care options through video conferencing, mobile apps, and online platforms. This is particularly beneficial for individuals in rural areas or those with limited mobility, overcoming geographical barriers to treatment.

Virtual services encompass a range of interventions, including therapy sessions, psychiatric evaluations, and medication management. The strategic alliance between Rogers Behavioral Health and Lyra Health exemplifies this trend, aiming to enhance the full continuum of care through innovative digital solutions.

However, ensuring equitable access and addressing digital literacy gaps remain crucial considerations for widespread telehealth adoption.

Integrated Behavioral Health Models

Integrated behavioral health represents a shift towards holistic care, embedding mental health services within primary care settings and other healthcare environments. This approach aims to address both physical and mental health needs concurrently, recognizing their interconnectedness.

Children’s Nebraska’s new Behavioral Health & Wellness Center exemplifies this model, prioritizing access, integration, and early intervention in pediatric mental healthcare. Such integration reduces stigma, improves patient outcomes, and streamlines care coordination.

A comprehensive and integrated approach, highlighted at Session 1, is vital for effectively addressing behavioral health challenges across the lifespan.

Early Intervention Programs for Youth

Early intervention programs are crucial for addressing mental health challenges in young people, preventing escalation into more severe conditions later in life. Recognizing that untreated mental health issues in youth can persist into adulthood is paramount.

Addressing the mental health of young individuals proactively is essential, as highlighted at Anthropy 2025. These programs often focus on building resilience, coping skills, and providing support within school and community settings.

Investing in early intervention is a preventative measure, fostering healthier futures and reducing the long-term burden on mental healthcare systems.